In the same section

- Polytech

- 4MAT

- Research

- Microstructure control of materials

-

Share this page

Microstructure control of materials

- NDIAMO Project

-

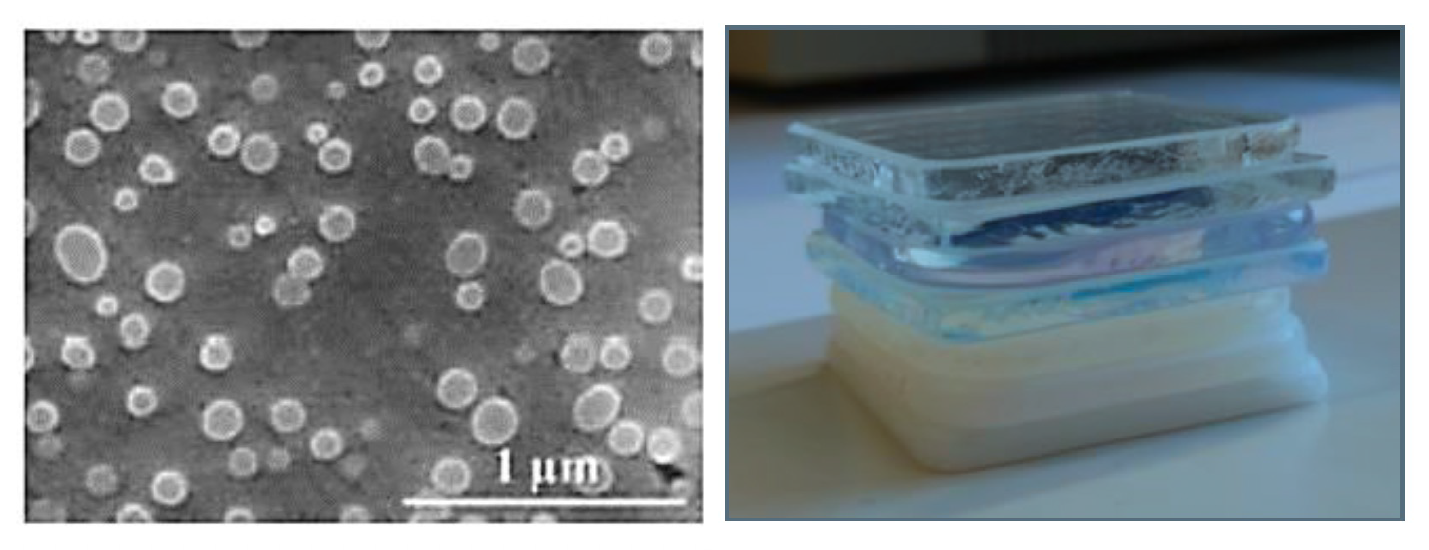

The characterization of the amorphous structure of glass is still a major challenge in Materials Science. It is indeed much more complex than for their crystalline cousins.

The local characterization is even more complex. In the present project we propose to use Transmission Electron Microscopy to measure ‘Pair Distribution Fonctions (e-PDF)’ at the local scale in close collaboration with the world-renown Brussels-based company

Nanomegas. The materials investigated will be opalescent glasses whose optical properties are tuned by the size of the nano- to micro-scale phase separation. Those glasses are developed in collaboration with the European Research Centre of AGC, world leader in flat glass production.

Contact(s) : S. GODET (Promotor)

- AEROCT - SKYWIN Project

-

Description project :

1. its inherent process-induced defects population,

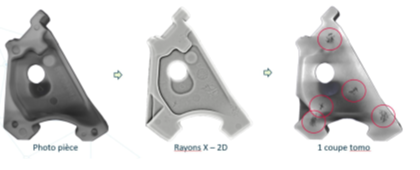

Additive Manufacturing can be considered as a revolution in the aeronautic field, promising an increased design freedom and improved performances. However, aeronautics is governed by tight specifications on structural health, usually with a “zero-defect” policy when it comes to accepting parts. In this regard, AM implementation in the aeronautic field is inhibited for several reasons :

2. a lack of standards dedicated to AM noncritical defects,

3. a systematic use of 3D computed tomography for qualifying 3D-printed parts, due to its high precision and despite the high time consumption and cost associated with such NDT method.

Mission(s) of 4MAT : The AEROCT project, run by Belgian NDT companies X-RIS, MPP, Belgian AM PME Any-Shape and ULB & ULiège, aims at helping the implementation of the Selective Laser Melting (SLM) AM technology in the aeronautic industry, by tackling several approaches.

First, the goal of the NDT industrial partners is to develop a tomograph optimized for AM applications, in terms of cost and configurations. This goes hand in hand with questioning the massive use of tomography, comparing to other NDT method (such as radiography and dye penetrant testing), towards the definition of business rules that tailor the use of tomography to specific inspection cases.

On the ULB side, 4MAT and ATM labs tackle a fundamental point of view, aiming at identifying the causes of the defects formation & their consequences during tensile and fatigue solicitations, so as to introduce corrective measures during the process, or at least to identify critical zones to be inspected in the studied framework.

Contact(s) : S. GODET (Promotor) – A. CHABOT (Post-Doc Researcher)

- COMPOST Project

-

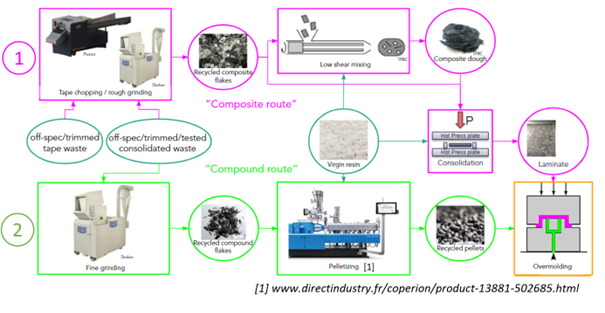

Syensqo is a world leader in terms of composite manufacturing and application, with a major emphasis on sustainability.

In the COMPOST project, the promises of recyclable thermoplastic composites are put to a “reality test”, by demonstrating the full chain needed to reproduce stamped and overmolded parts using production waste. Two main mechanical recycling routes are evaluated: (1) compounding finely ground recyclates into pellets suitable for injection molding and (2) direct consolidation of more coarsely ground recyclates into sheet molding compound plates. The effects of multiple recycling steps on the mechanical and physical material properties are measured at the micro-, meso- and macro-scale. Experimental observations are translated into numerical models for use in predictive macro-scale part simulations. Economic viability, environmental sustainability and technical feasibility of the full recycling chain is quantified based on the obtained performance of fully recycled stamped and overmolded demonstrator parts

Contact(s) : S. GODET (Promotor) – A. CHABOT (Post-Doc Researcher)

- Hy-FUEL Innoviris Project

-

Syensqo is a world leader in terms of composite manufacturing and application, with a major emphasis on sustainability.

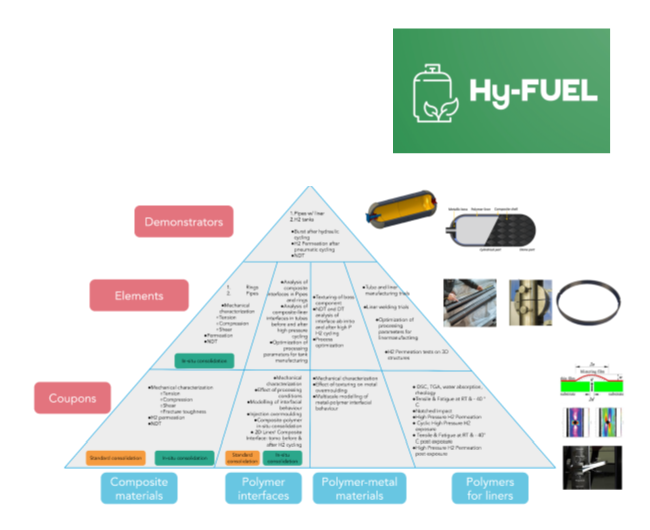

Hy-FUEL (Hydrogen tanks: Future Utilisation of Ecofriendly and Light thermoplastics) is a research project focused on the development of an eco-friendly fully thermoplastic high-rate compatible solution for hydrogen pressure vessels for the road mobility sector. The project is a partnership between Syensqo, ULB and VUB, and focuses on the development and selection of the materials for both the liner and composite overwrap. The multiple component nature of a H2 tank creates the presence of different interfaces, both polymer-polymer (or polymer-composite) and metal-composite. The understanding, control and optimization of these interfaces is key to optimising the usage of material in the tank and ensuring safety throughout its lifecycle. To achieve these goals, a building block approach for the characterization of materials for hydrogen applications, from coupon testing to lab scale full tank burst and hydrogen testing, will be developed and implemented. Through all the stages of the testing pyramid, extensive in-situ damage monitoring techniques are used, which in combination with numerical modelling allow a thorough understanding of the material behaviour during the loading processes.

Missions at 4MAT:

1. Interfaces characterization at micro & meso scales

2. Metal texturing and adhesion improvements

3. Support in microscopy analysis

Contact(s) : S. GODET (Promotor) – A. CHABOT (Post-Doc Researcher)